Przejdź do trybu offline z Player FM !

Podcast Ep. #46 – Tow-Steered Composite Materials with iCOMAT

Manage episode 282902686 series 1757905

Dr Evangelos Zympeloudis is the CEO and co-founder of iCOMAT, a company based in the UK that is developing automated manufacturing equipment for tow-steered composites. Fibre-reinforced plastics, such as carbon-fibre or glass-fibre composites, hold great promise for high-performance and lightweight design due to their excellent stiffness and strength properties at low material density. Traditional fibre-reinforced plastics are manufactured using straight uni-directional fibres or with straight fibres woven into a fabric.

Dr Evangelos Zympeloudis is the CEO and co-founder of iCOMAT, a company based in the UK that is developing automated manufacturing equipment for tow-steered composites. Fibre-reinforced plastics, such as carbon-fibre or glass-fibre composites, hold great promise for high-performance and lightweight design due to their excellent stiffness and strength properties at low material density. Traditional fibre-reinforced plastics are manufactured using straight uni-directional fibres or with straight fibres woven into a fabric.

Generally speaking, a fibre-reinforced composite derives its strength by aligning the fibres with the direction of the dominant load path. The novelty of tow-steered composites is that strips of composite material, so-called fibre tows, are steered along curvilinear paths such that the fibre direction is not straight, but varies continuously from point to point. This characteristic has benefits in structural design as the reinforcing fibres can now be used to smoothly tailor stiffness and strength throughout the structure. For example, tow-steered composites can be used to curve the reinforcing fibres around windows in an aircraft fuselage in order to improve strength and facilitate net-shape manufacturing.

Generally speaking, a fibre-reinforced composite derives its strength by aligning the fibres with the direction of the dominant load path. The novelty of tow-steered composites is that strips of composite material, so-called fibre tows, are steered along curvilinear paths such that the fibre direction is not straight, but varies continuously from point to point. This characteristic has benefits in structural design as the reinforcing fibres can now be used to smoothly tailor stiffness and strength throughout the structure. For example, tow-steered composites can be used to curve the reinforcing fibres around windows in an aircraft fuselage in order to improve strength and facilitate net-shape manufacturing.

In this episode of the Aerospace Engineering Podcast, Evangelos and I talk about:

- his background as an engineer and entrepreneur

- the manufacturing challenge of making defect-free tow-steered composites

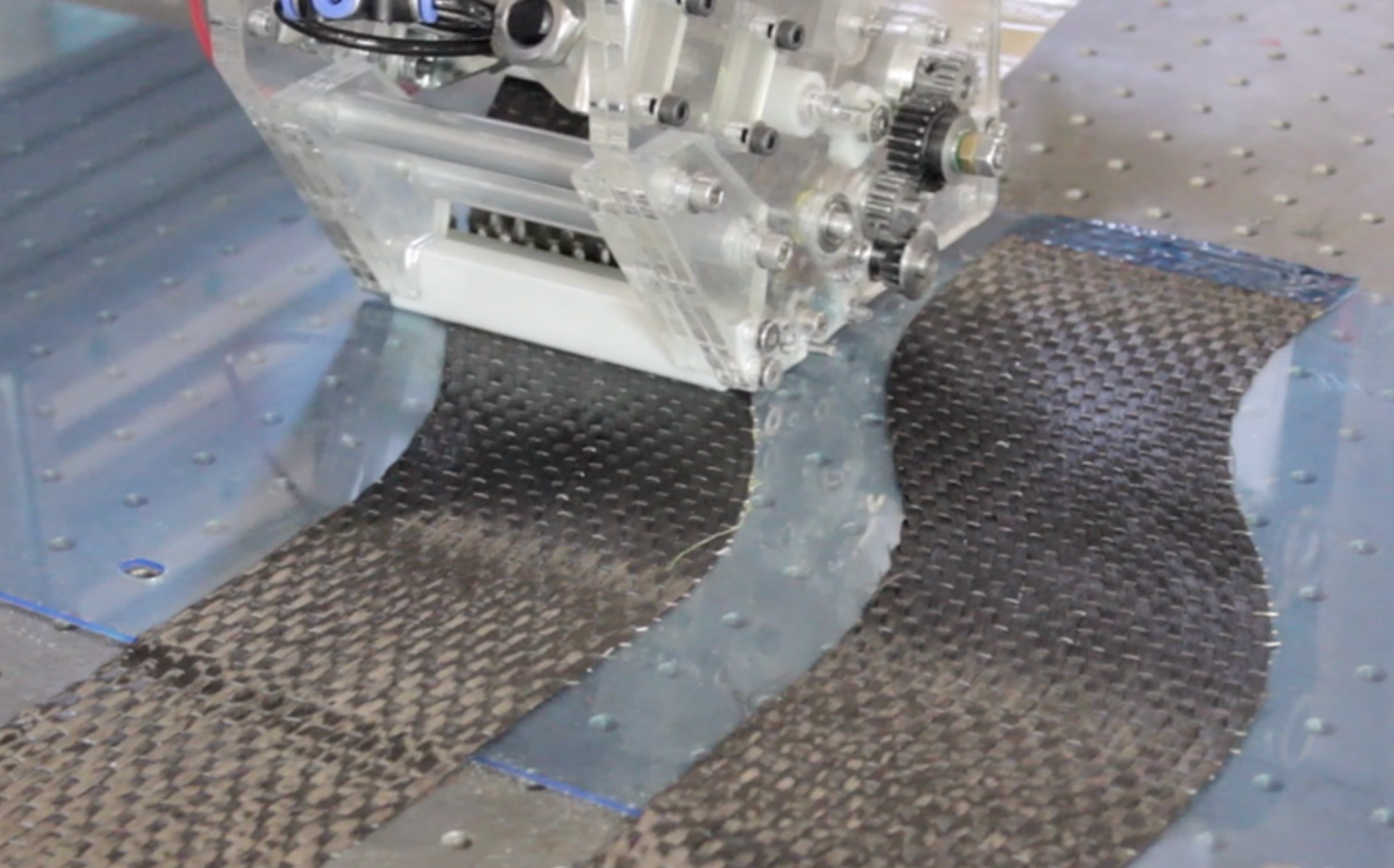

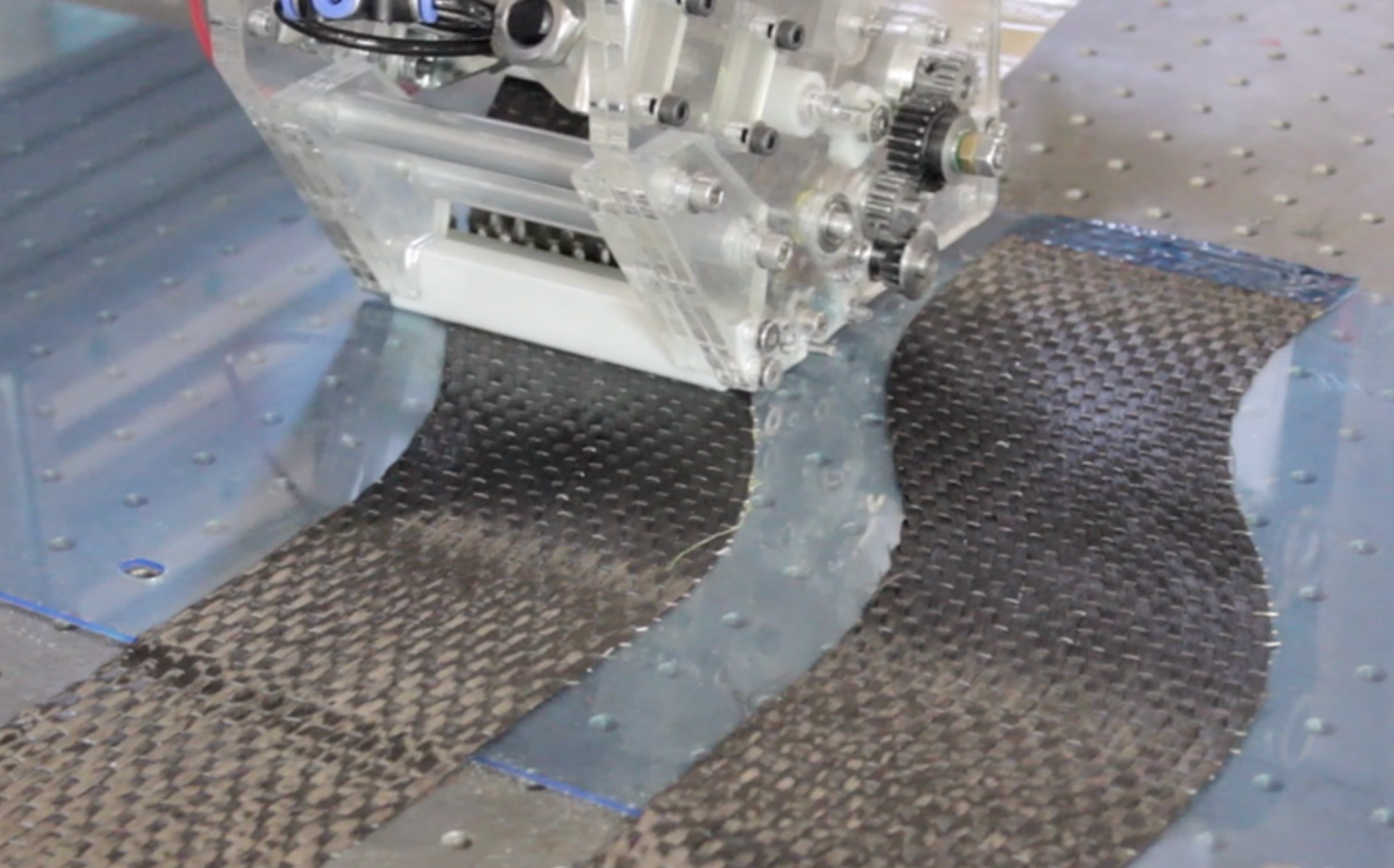

- the capabilities of iCOMAT’s rapid tow-shearing process

- the benefits of tow-steering for manufacturing cost and design

- and some of the projects iCOMAT is currently working on

This episode of the Aerospace Engineering Podcast is brought to you by my patrons on Patreon. Patreon is a way for me to receive regular donations from listeners whenever I release a new episode, and with the help of these generous donors I have been able to pay for much of the expenses, hosting and travels costs that accrue in the production of this podcast. If you would like to support the podcast as a patron, then head over to my Patreon page. There are multiple levels of support, but anything from $1 an episode is highly appreciated. Thank you for your support!

Disclosure: I currently work with iCOMAT on a number of projects and am a consultant to the company.

Selected Links from the Episode

- iCOMAT webpage, LinkedIn

- iCOMAT’s technology

- Video of the Rapid Tow-Shearing process

- Tow-steered composites overview:

50 odcinków

Manage episode 282902686 series 1757905

Dr Evangelos Zympeloudis is the CEO and co-founder of iCOMAT, a company based in the UK that is developing automated manufacturing equipment for tow-steered composites. Fibre-reinforced plastics, such as carbon-fibre or glass-fibre composites, hold great promise for high-performance and lightweight design due to their excellent stiffness and strength properties at low material density. Traditional fibre-reinforced plastics are manufactured using straight uni-directional fibres or with straight fibres woven into a fabric.

Dr Evangelos Zympeloudis is the CEO and co-founder of iCOMAT, a company based in the UK that is developing automated manufacturing equipment for tow-steered composites. Fibre-reinforced plastics, such as carbon-fibre or glass-fibre composites, hold great promise for high-performance and lightweight design due to their excellent stiffness and strength properties at low material density. Traditional fibre-reinforced plastics are manufactured using straight uni-directional fibres or with straight fibres woven into a fabric.

Generally speaking, a fibre-reinforced composite derives its strength by aligning the fibres with the direction of the dominant load path. The novelty of tow-steered composites is that strips of composite material, so-called fibre tows, are steered along curvilinear paths such that the fibre direction is not straight, but varies continuously from point to point. This characteristic has benefits in structural design as the reinforcing fibres can now be used to smoothly tailor stiffness and strength throughout the structure. For example, tow-steered composites can be used to curve the reinforcing fibres around windows in an aircraft fuselage in order to improve strength and facilitate net-shape manufacturing.

Generally speaking, a fibre-reinforced composite derives its strength by aligning the fibres with the direction of the dominant load path. The novelty of tow-steered composites is that strips of composite material, so-called fibre tows, are steered along curvilinear paths such that the fibre direction is not straight, but varies continuously from point to point. This characteristic has benefits in structural design as the reinforcing fibres can now be used to smoothly tailor stiffness and strength throughout the structure. For example, tow-steered composites can be used to curve the reinforcing fibres around windows in an aircraft fuselage in order to improve strength and facilitate net-shape manufacturing.

In this episode of the Aerospace Engineering Podcast, Evangelos and I talk about:

- his background as an engineer and entrepreneur

- the manufacturing challenge of making defect-free tow-steered composites

- the capabilities of iCOMAT’s rapid tow-shearing process

- the benefits of tow-steering for manufacturing cost and design

- and some of the projects iCOMAT is currently working on

This episode of the Aerospace Engineering Podcast is brought to you by my patrons on Patreon. Patreon is a way for me to receive regular donations from listeners whenever I release a new episode, and with the help of these generous donors I have been able to pay for much of the expenses, hosting and travels costs that accrue in the production of this podcast. If you would like to support the podcast as a patron, then head over to my Patreon page. There are multiple levels of support, but anything from $1 an episode is highly appreciated. Thank you for your support!

Disclosure: I currently work with iCOMAT on a number of projects and am a consultant to the company.

Selected Links from the Episode

- iCOMAT webpage, LinkedIn

- iCOMAT’s technology

- Video of the Rapid Tow-Shearing process

- Tow-steered composites overview:

50 odcinków

Wszystkie odcinki

×Zapraszamy w Player FM

Odtwarzacz FM skanuje sieć w poszukiwaniu wysokiej jakości podcastów, abyś mógł się nią cieszyć już teraz. To najlepsza aplikacja do podcastów, działająca na Androidzie, iPhonie i Internecie. Zarejestruj się, aby zsynchronizować subskrypcje na różnych urządzeniach.